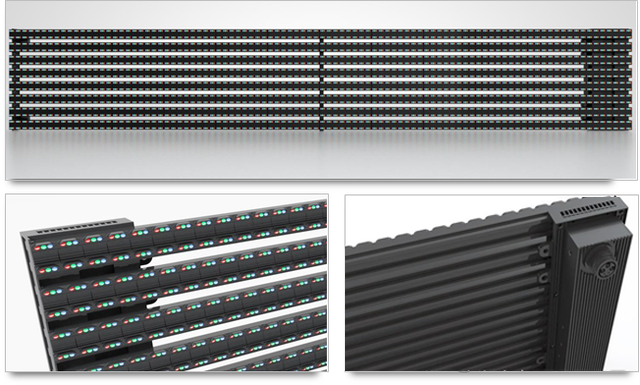

The breakthrough design of LED grid screens breaks through the many limitations of traditional LED displays on building walls. LED grille screens have a product form that is strip shaped, hollow out, and transparent, also known as curtain screens, curtain wall screens, grille screens, etc., due to their light weight, small wind load, and flexible installation. Widely used in outdoor walls, glass curtain walls, building roofs, as well as outdoor anti-aircraft guns, stage LED rental displays, etc., it is a new generation of outdoor LED display products, very suitable for building super large outdoor displays. It can make engineering more flexible and adaptable, with multiple options and more effortless. Now, let's learn about the design concept and product advantages of grille screens, as well as how they bring convenience to engineering.

1. Lightweight, with low wind load, suitable for large display screens.

Compared with traditional LED display screens, it is 60% -80% lighter in weight, greatly reducing the strength and weight of the basic structure of the display screen. It is especially suitable for large-sized LED display screens, with a transparency rate of 40% -50% and extremely strong wind resistance, effectively reducing the strength and weight of the basic structure of LED display screens.

2. Capable of low power consumption

The true energy-saving comes from high brightness, high luminous efficiency LED lights, and high conversion efficiency power supplies.

3. IP67 high protection level

Many traditional display screens will indicate the protection level, with two data points: the number of front IP and the number of back IP. And the grille screen has a high protection level of IP67, because the concept of IP67 is immersion waterproofing, that is, the overall soaking of the product ensures the safety and stability of use.

4. Equipped with a good automatic heat dissipation system, there is no need to increase air conditioning heat dissipation.

Each LED strip is made of aluminum alloy material, with good transparency around it, which can achieve good self heat dissipation. At the same time, isolate the power supply, control, etc. from the luminescent materials without the need for special cooling systems, such as LED screens.

5. Highly integrated

Highly integrated (with built-in power supply and receiving card, each unit can work independently; power and signal are plugged in). Through unique electronic circuit design, the number of lamp strips connected has been reduced. Every 16 use a set of power and signal connectors, and under the same conditions, the poor connection rate can be reduced by 94%.

6. Easy to install

No steel structure installation, no air conditioning required, can be installed front or rear. The product is lightweight, easy to install, and can be installed front or back; The product does not require air conditioning, and on one side, the low power consumption of the product can also be seen. Electric energy is more efficiently converted into light rather than heat.

7. Simple structure and convenient maintenance.

By using a small amount of components, it is easy to stick to the wall without damaging the wall and foundation. Pre maintenance or post maintenance can be conveniently implemented as needed. If pre maintenance is used, there is no need to set up a repair channel.

8. Integrated design of control box and installation structure.

The control box is both a part of the screen and a part of the screen. Greatly simplifies the screen structure, and there are no visible plugs or connections on the appearance of the screen. Not only is it aesthetically pleasing, but it also greatly improves the stability of the screen. High brightness, high refresh rate, high grayscale, can be played during the day.

Post time: Jan-09-2024