With the rapid development of LED technology, LED displays have gradually shifted from large pitch outdoor products to indoor close-up viewing, replacing DLP, LCD splicing, and projection products. Nowadays, the application of small pitch LED displays has become increasingly common. So, daily issues and maintenance of products have become more important, which not only ensures the work efficiency of the user unit, but also extends the service life of the product.

Waterproof ≠ moisture-proof

1. Check the display screen daily to ensure that the ambient temperature is ≤ 30 ℃ and the humidity is ≤ 60% RH, which meets the working conditions.

2. Use the display screen and supporting equipment at least twice a week, for 2 hours each time; If the display screen is not used for 5 consecutive natural days, please perform preheating, dehumidification, and dehumidification before using it again.

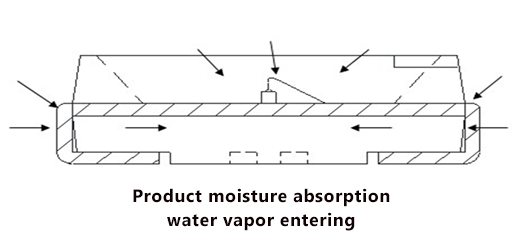

Moisture prevention is to prevent moisture and moisture. The packaging materials for LED display devices are mainly plastic materials such as epoxy resin. Plastic belongs to polymer materials, and the gaps between polymer molecules are large. Vapour water molecules can penetrate into the shell through the gaps. LED products are moisture sensitive components, and they will slowly absorb moisture during use.

The hazards of LED display devices being damp

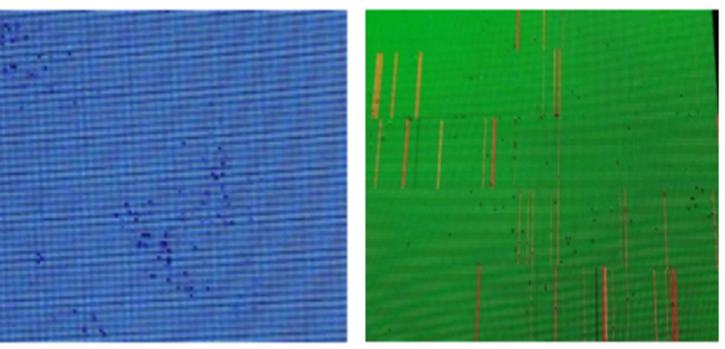

LED display devices are affected by moisture, and water vapor seeps into the devices. When halogen containing water vapor in the air seeps into the devices and is powered on, the halogen in the water vapor will react electrochemically with the metal inside the devices. In severe cases, it can cause chip short circuit, leakage, or electrode drop, resulting in blind lights and abnormal string lighting of the display screen devices.

LED device storage

When transporting and storing LED devices, objects can be used to elevate them and waterproof and moisture-proof preparations should be made. Meanwhile, The storage environment of LED devices is equally important, and it is recommended to monitor temperature and humidity. The optimal storage environment is: temperature<30 ℃, humidity<60% RH, and desiccant should be added during transportation and storage.

Packaging of spare modules/HUB/receiving cards

Spare module HUB、 Receive cards, etc., vacuum package or seal them and dispose of them with desiccant.

Indoor dehumidification

1. Physical dehumidification method: Prevent quantitative use of desiccants indoors to reduce moisture in the air.

2. Moderate ventilation: Ensure that moderate ventilation accelerates the rate of water vapor evaporation and reduces the relative humidity of the indoor environment when the weather is not humid and there is wind.

3. Air conditioning dehumidification: Air conditioning dehumidification can be used in humid weather to reduce moisture exposure.

4. Use a specialized dehumidifier for dehumidification.

Screen dehumidification in use

After installation, the screen body needs to be frequently lit up for use. If the display screen is not used for a long time (usually 5-10 days), dehumidification treatment should be carried out before use, and accumulated moisture inside the screen body should be gradually removed by gradually increasing brightness and slowly heating up, gradually increasing brightness to remove moisture.

Precautions for using LED display screens - disinfectant

Please use 84 disinfectant containing (chlorine, bromine) and high-efficiency disinfectant with caution to directly spray and disinfect the storage, production, and usage environment of LEDs.

The disinfectants we commonly use include 84 disinfectant solution, ethanol (alcohol) disinfectant solution, brominated disinfectant water, chlorine dioxide disinfectant tablets, quaternary ammonium salt disinfectants (Jie'er Mi), etc. The above disinfectants can have a disinfection effect on surfaces such as tabletops and floors. However, improper use of chlorine containing 84 disinfectant, bromine containing disinfectant, and chlorine dioxide disinfectant tablets may cause corrosion to our LED display screens and beads.

Screen dust removal/impurities

To achieve the best display effect, it is recommended to use an anti-static soft brush to clean the dust on the surface of the display screen every month.

As technology matures and costs decrease, the application of small pitch LEDs in commercial display markets such as conference rooms, education, shopping malls, and cinemas will become increasingly common, and attention should be paid to the daily issues and maintenance of products.

Post time: Oct-21-2024