LED Display Screen High-definition Seamless Splicing P1.25 P1.53 P1.86 P2.5 Small Pitch Full-color Video Wall

Customized Design

This Series is also tailor-made for specific demands in sizes. which, currently supports only seperated connection of power and signal ports.

The following is the detailed process for customizing display screens. If you have any needs, please contact us in a timely manner.

.jpg)

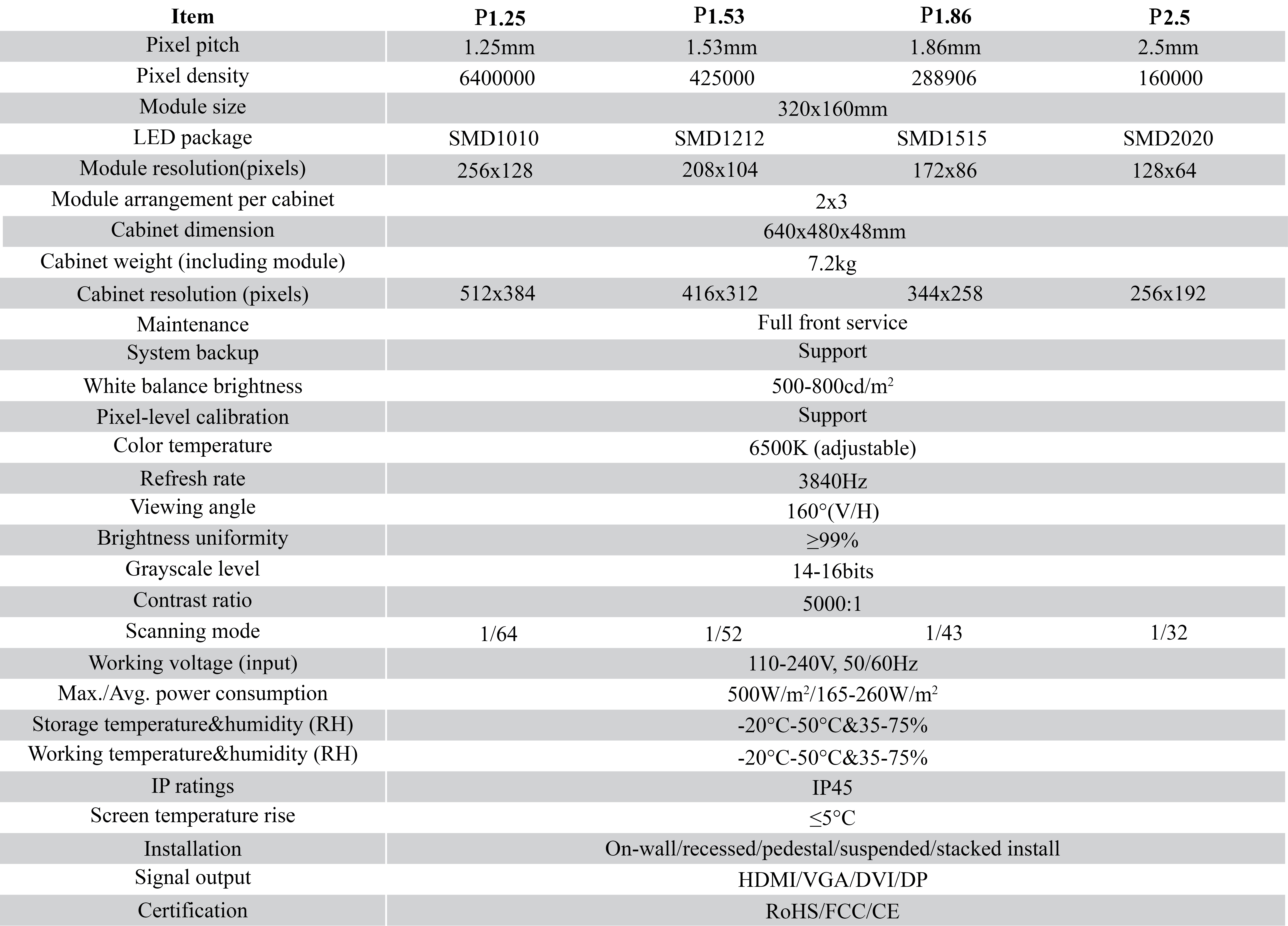

Specification

Introduction

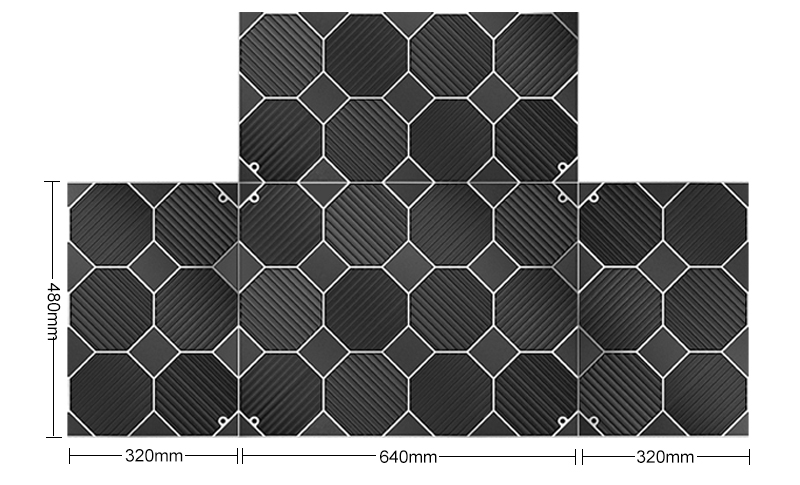

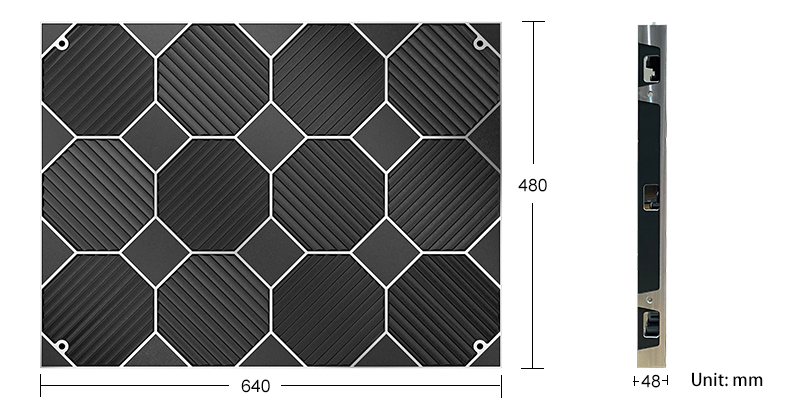

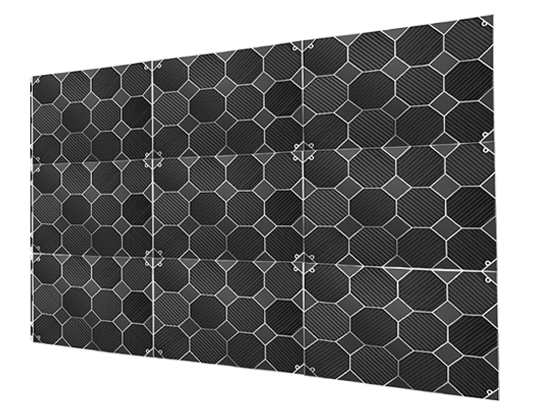

This series has the frame of honeycomb. The cabinet is made precisely through CNC machines, and is capable to keep firm in structure when under stress, anddissipate heat quickly.

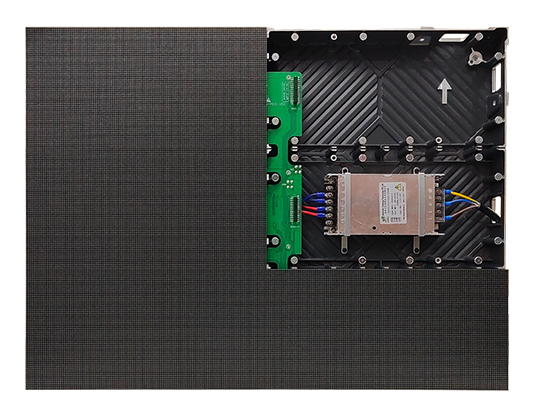

Inside the structure, all modules are mounted directly, cordlesly. It also allows redundancy system and PSU unit.

This series adopts the installation method of front maintenance magnets, which is very convenient for both installation and maintenance. It saves maintenance space on the back of the display screen, making it possible to maximize the use of environmental space and reduce the difficulty of later maintenance work in the expensive indoor installation environment.

This series of enclosures can be quickly assembled and installed in any installation environment, which is very fast and time-saving. At the same time, it can be spliced into different sizes according to your needs, which can reduce costs. This is a good choice for installing indoor small pitch display screens.

Advantage

Full color hard screen panel structure, surface light bead design, precise density presenting 4K high-definition vision, without the inevitable residual image and flicker phenomenon on ordinary panels, enjoying a stunning visual experience.

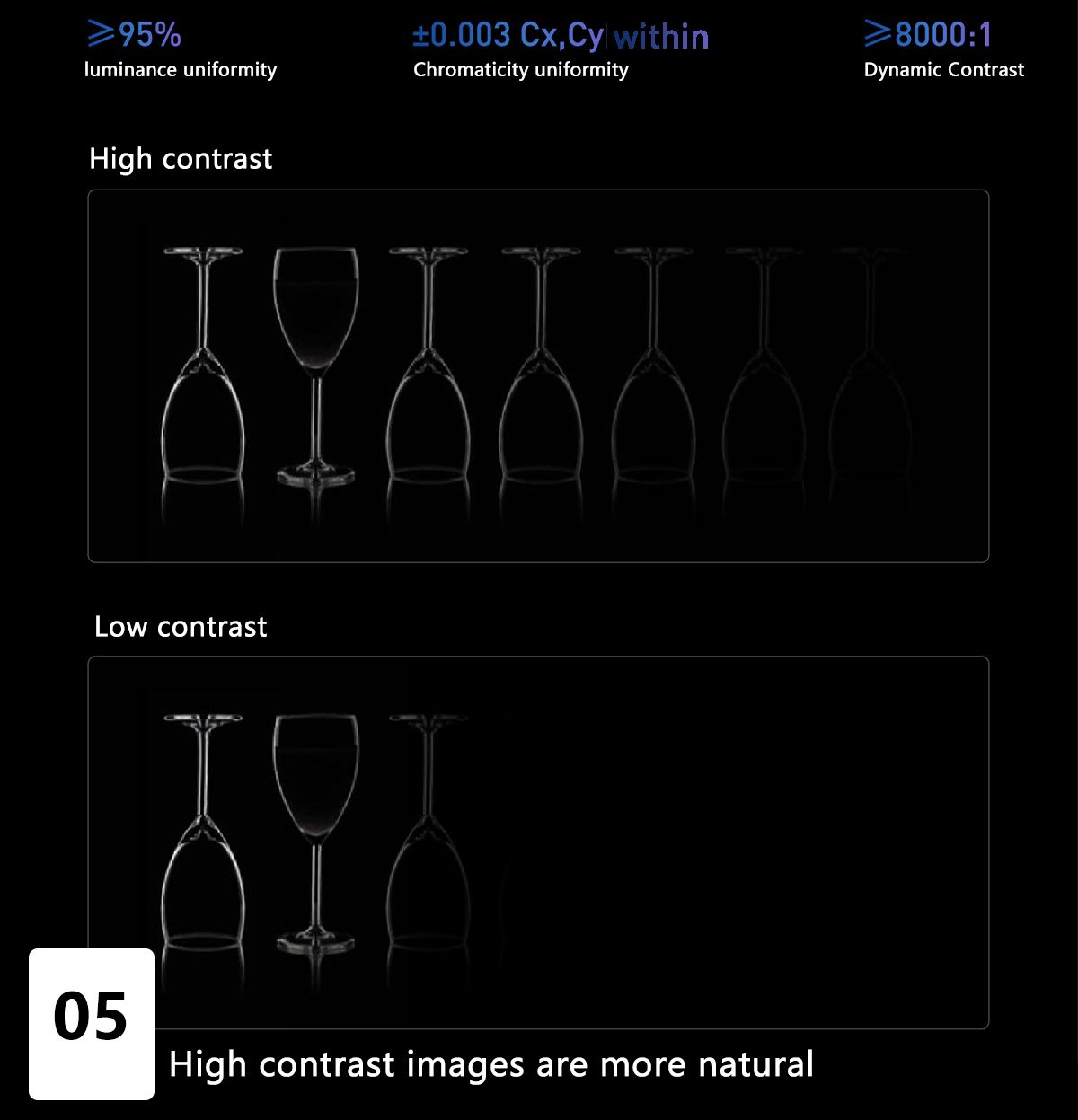

Using Kinglight and Nationstar brand LED chips, it has a longer lifespan, high sustained brightness, high contrast, good mixing effect, and is safer and more stable.

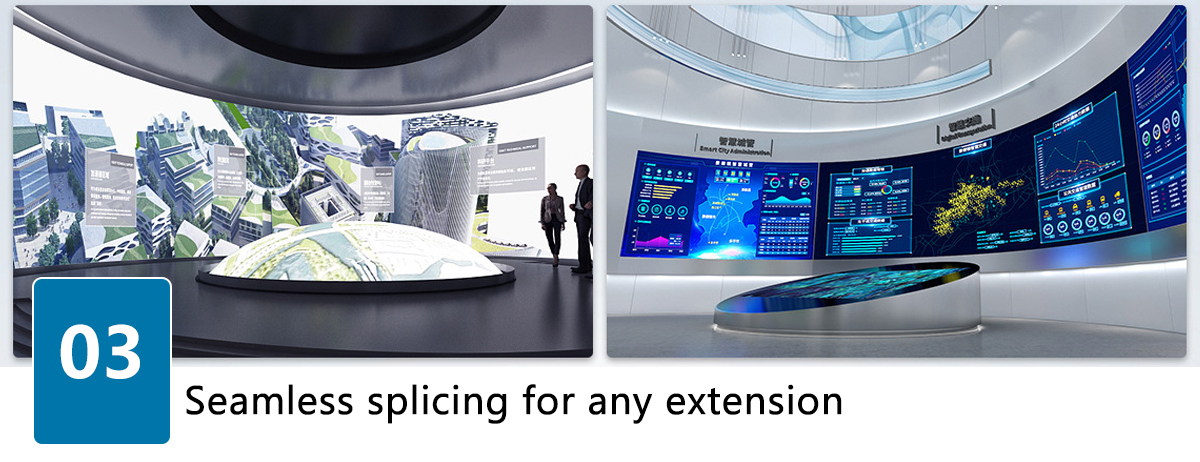

High precision unit screen structure ensures consistent point spacing, seamless module splicing achieves high-definition large screen combination, presenting high-definition large screen style.

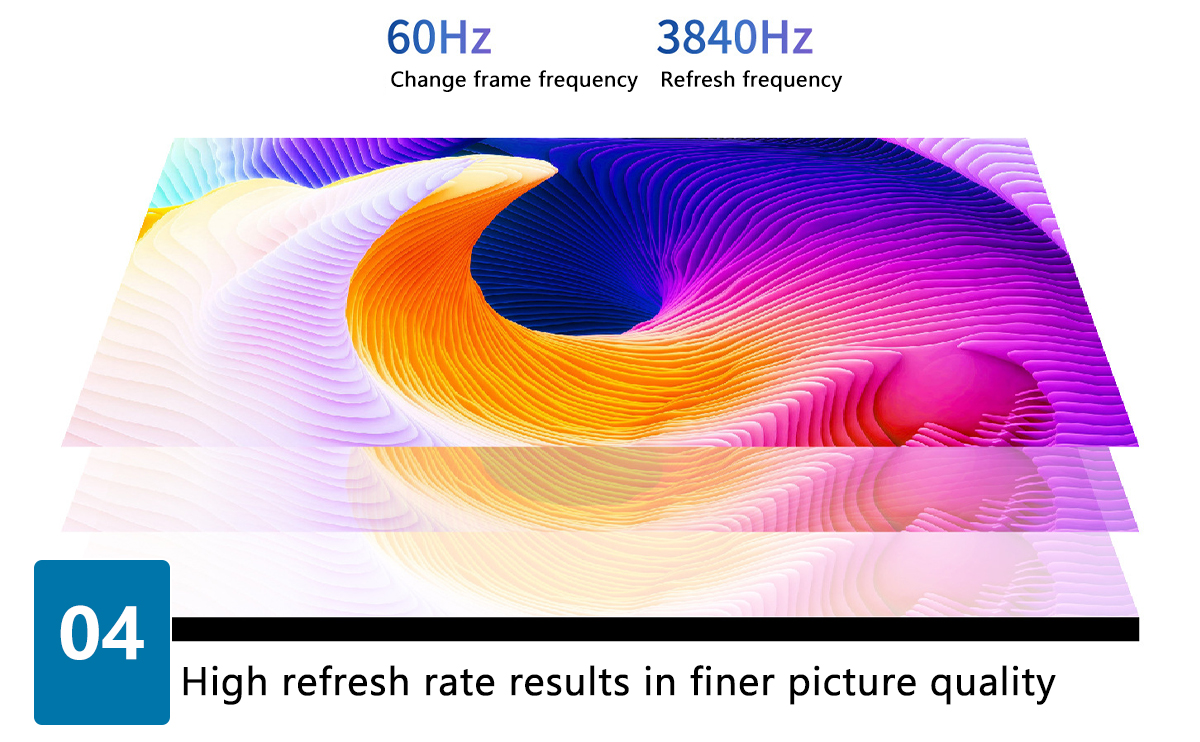

With a high refresh rate of up to 3840HZ and fast response speed, the screen display shows no ghosting or flickering under 1/2800 second of professional camera and videography, and the image display is smooth and stable.

Selected PWM driver IC, natural grayscale transition, realistic image display, and vibrant colors.

Under the PWM driver IC standard, the color gamut is wider, greatly improving the color gamut space, accurately presenting more levels of detail, and bringing a better picture quality experience.

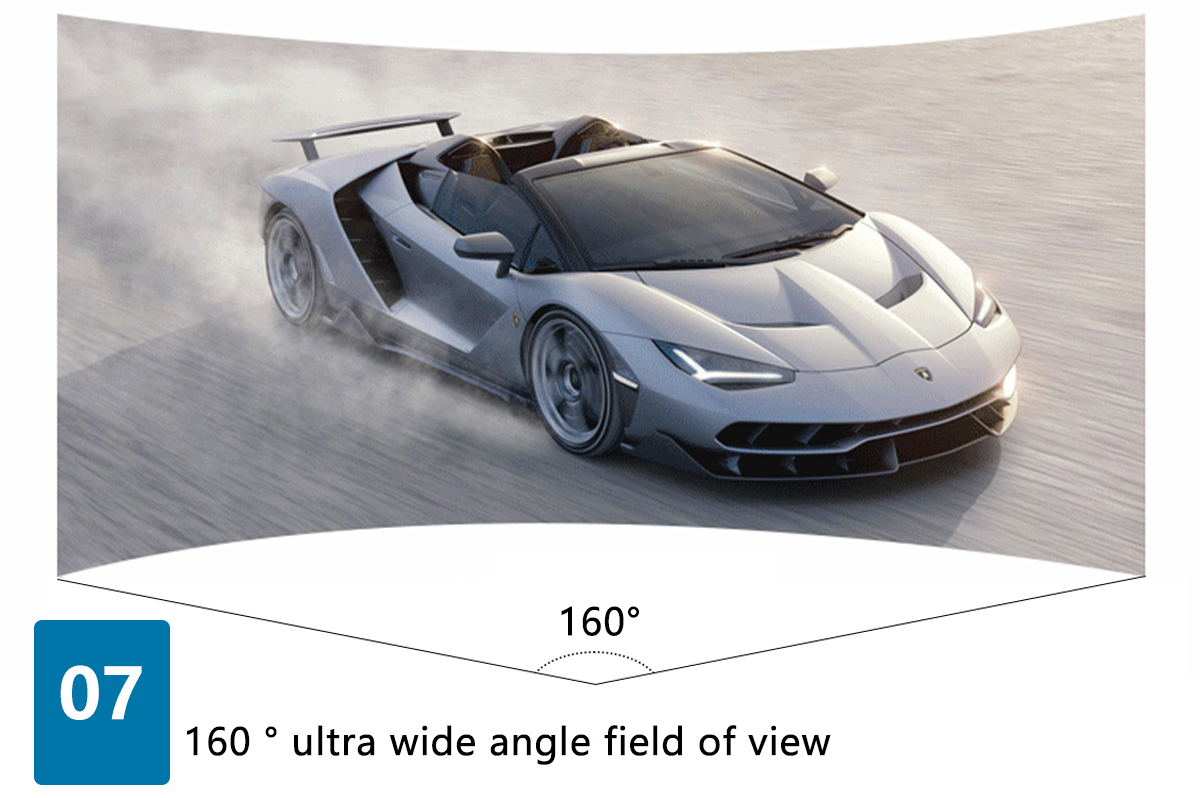

The surface mounted lamp beads have a large viewing angle, and are equipped with high-precision equipment and advanced technology, unique pit electromagnetic wave processing, distributed scanning technology, and modular technology to enhance reliability and stability.

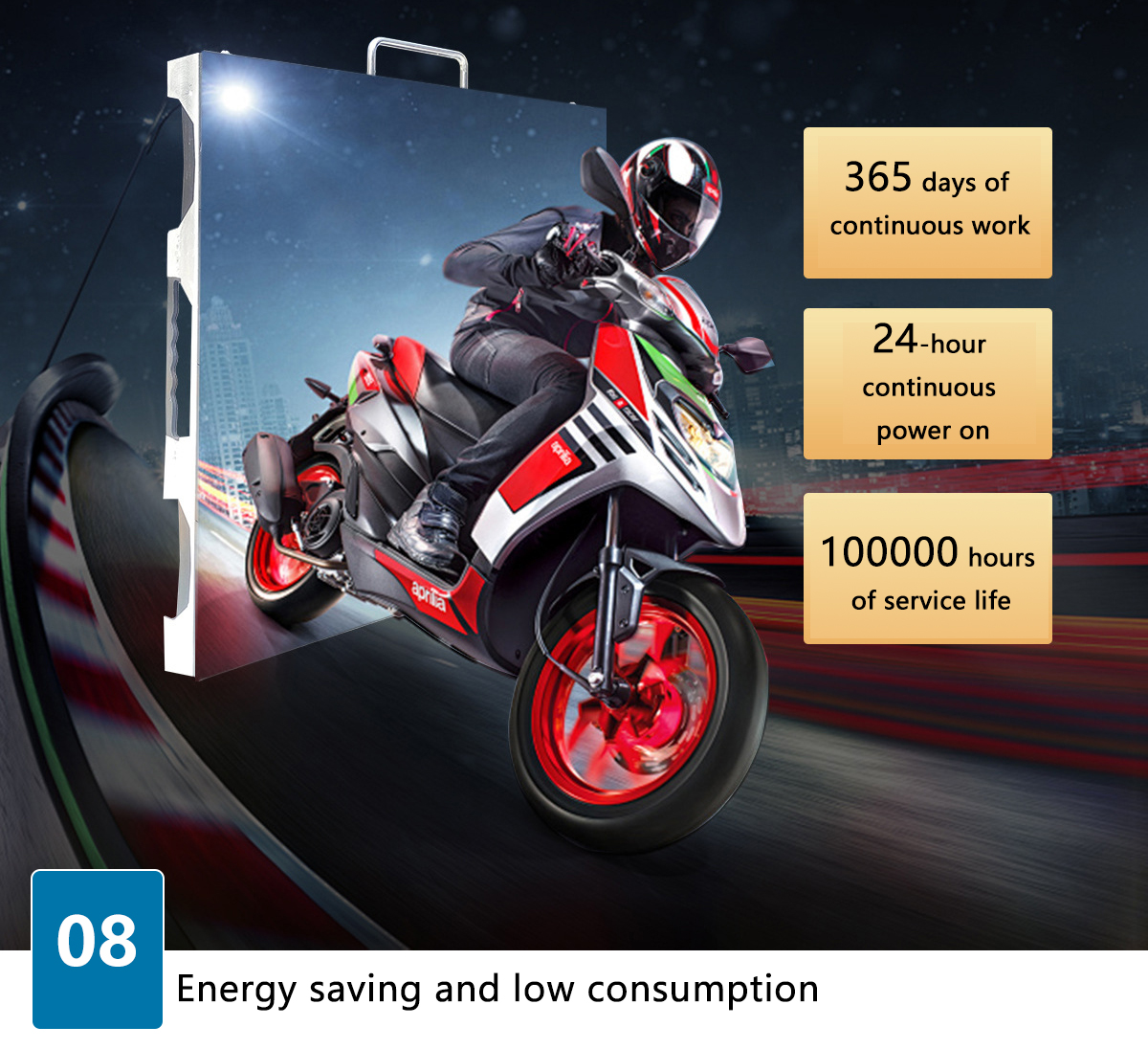

Using the sixth representative sticker beads, the unit board has a service life of over 100000 hours, actively utilizes circular resources, has low power consumption design, and supports 7X24 hours 365 days non-stop operation.

Support customized special screens such as curved, rectangular, S-shaped, and irregular shapes, which can realize various creative display screens with standard display ratios and unchanged images.

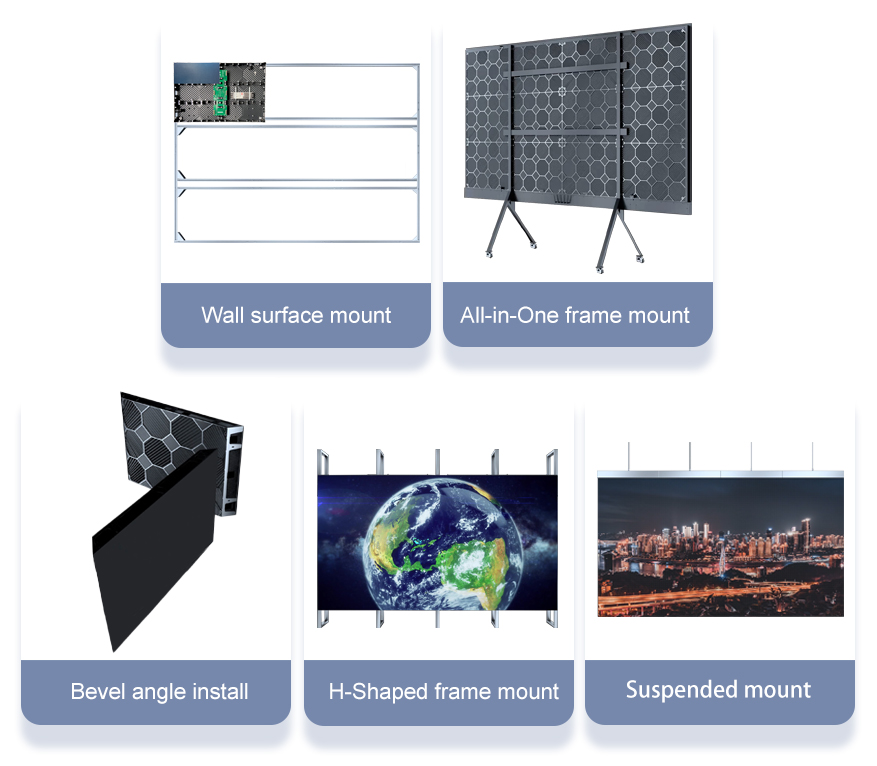

Diversified Installation

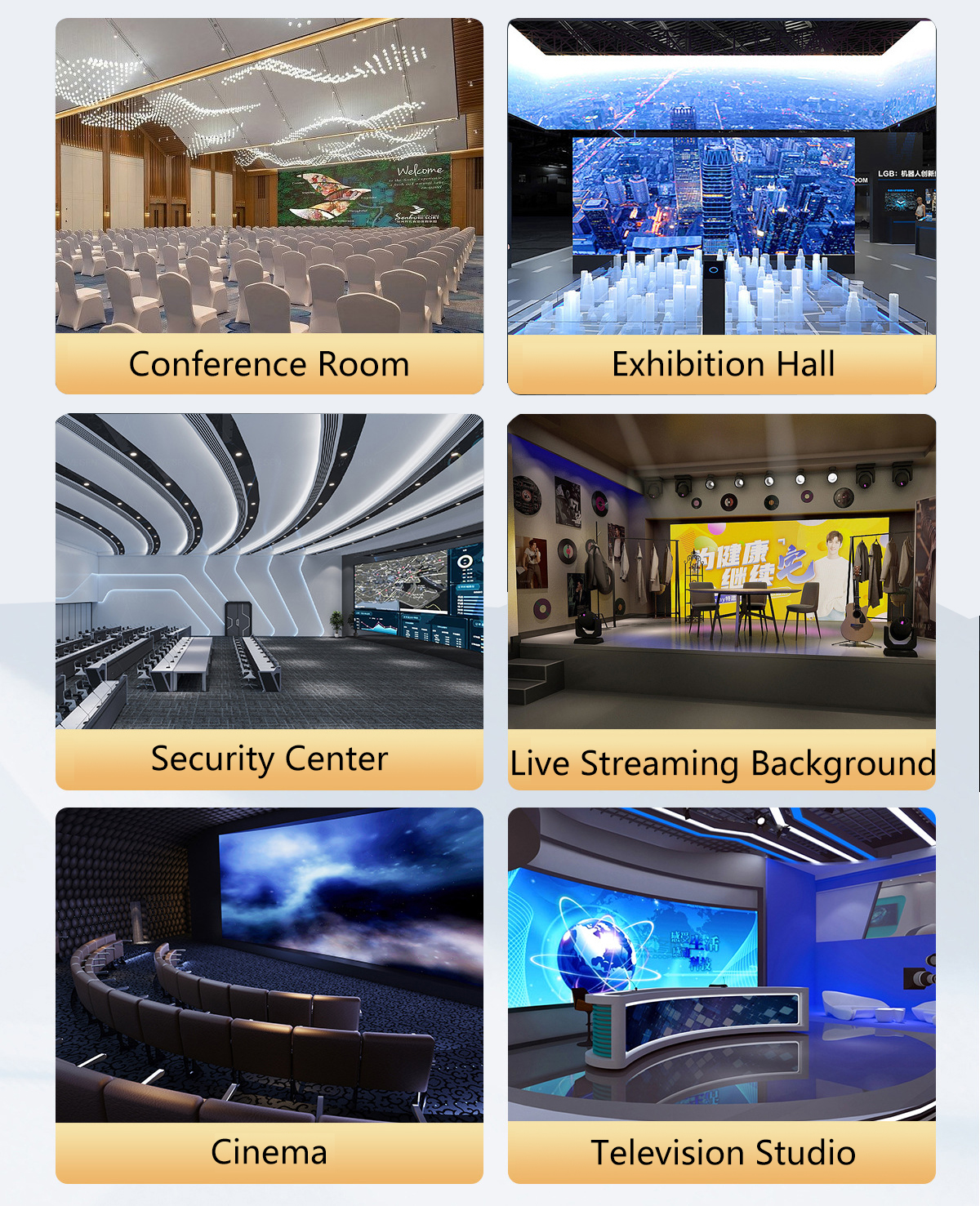

Application Scenarios

Mainly suitable for indoor high-definition application places such as monitoring command centers, digital exhibition halls, conference rooms, performance halls, and experimental teaching.

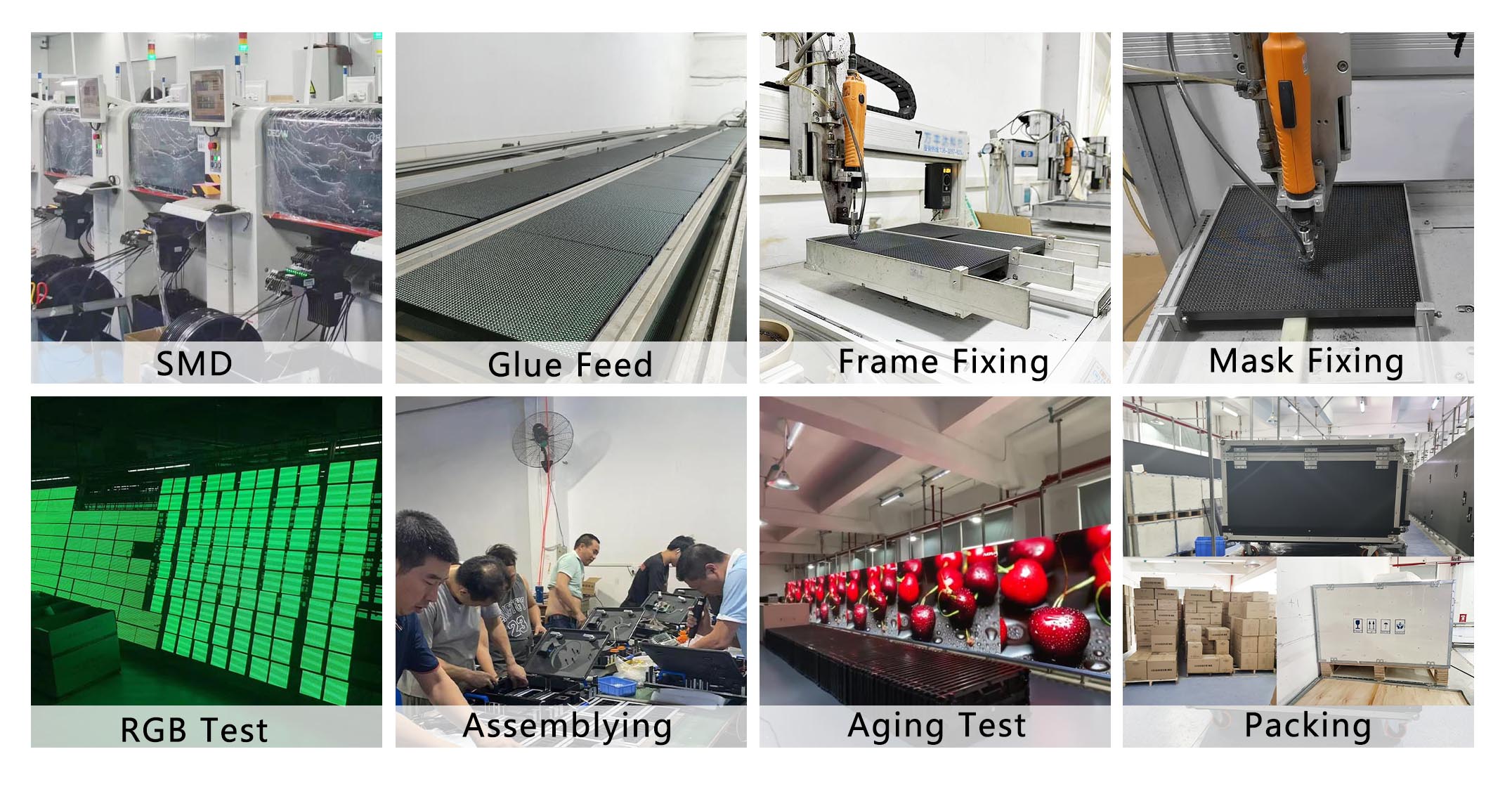

Production Process

We have professional LED display production equipment and assembly personnel. You only need to provide your needs, and we will provide you with comprehensive professional services from scratch. From developing production plans to the production and assembly of displays, we will ensure quality and quantity. You can rest assured to cooperate with us.

LED Display Aging and Testing

Aging and testing of LED display modules involves simulating long-term operation to ensure reliability and stability. This process is critical to identifying and resolving potential issues, ultimately improving the efficiency and stability of the LED display.

Conducting burn-in testing is a critical step in quality control to ensure the overall performance and service life of the LED display.

The process of LED display aging test includes the following steps:

1. Verify that all LED display modules are installed correctly.

2. Check for any potential short circuits.

3. Make sure the modules are flat and arranged neatly.

4. Inspect the overall appearance for any damage or defects.

5. Use the online LED control system to light up the display.

This process is essential to evaluate the functionality and quality of the LED display and ensure its reliable and efficient operation.

Package

Flight case

Wooden Case

.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)