G-energy JPS300P 100-240V Input LED Screen Power Supply 5V 60A 300W

Product Main Specification

|

Output Power (W) |

Rated Input Voltage (Vac) |

Rated Output Voltage (Vdc) |

Output Current Range (A) |

Precision |

Ripple and Noise (mVp-p) |

|

300W |

100-240 |

+5.0 |

0-60 |

±5% |

≤200mVp-p @25℃ |

|

|

|

|

|

|

≤200mVp-p @-25℃

|

Environment Condition

|

Item |

Description |

Tech Spec |

Unit |

Remark |

|

1 |

Working temperature |

-30—50 |

℃ |

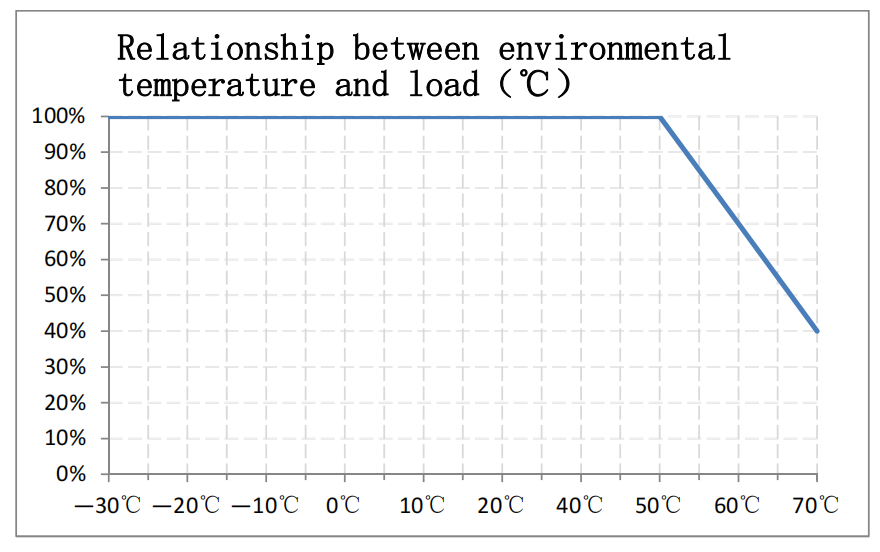

Referto the use of environmental temperature and load curve. |

|

2 |

Storing temperature |

-40—85 |

℃ |

|

|

3 |

Relative humidity |

10—90 |

% |

|

|

4 |

Heat dissipation method |

Fan cooling |

|

|

|

5 |

Air pressure |

80— 106 |

Kpa |

Electrical Character

|

1 |

Input character | ||||

|

Item |

Description |

Tech Spec |

Unit |

Remark |

|

|

1.1 |

Rated voltage range |

200-240 |

Vac |

Refer to the diagram of input voltage and load relation. |

|

|

1.2 |

Input frequency range |

47—63 |

Hz |

|

|

|

1.3 |

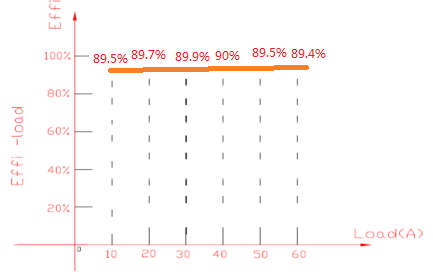

Efficiency |

≥85.0 |

% |

Vin=220Vac 25℃ Output Full Load (at room temperature) |

|

|

1.4 |

Efficiency factor |

≥0.40 |

|

Vin=220Vac Rated input voltage, output full load |

|

|

1.5 |

Max input current |

≤3 |

A |

|

|

|

1.6 |

Dash current |

≤70 |

A |

@220Vac Cold state test @220Vac |

|

|

2 |

Output character | ||||

|

Item |

Description |

Tech Spec |

Unit |

Remark |

|

|

2.1 |

Output voltage rating |

+5.0 |

Vdc |

|

|

|

2.2 |

Output current range |

0-40.0 |

A |

|

|

|

2.3 |

Output voltage adjustable range |

4.2-5.1 |

Vdc |

|

|

|

2.4 |

Output voltage range |

±1 |

% |

|

|

|

2.5 |

Load regulation |

±1 |

% |

|

|

|

2.6 |

Voltage stability accuracy |

±2 |

% |

|

|

|

2.7 |

Output ripple and noise |

≤200 |

mVp-p |

Rated input, output full load, 20MHz bandwidth, load side and 47uf / 104 capacitor |

|

|

2.8 |

Start output delay |

≤3.0 |

S |

Vin=220Vac @25℃ test |

|

|

2.9 |

Output voltage raise time |

≤90 |

ms |

Vin=220Vac @25℃ test |

|

|

2.10 |

Switch machine overshoot |

±5 |

% |

Test conditions: full load, CR mode |

|

|

2.11 |

Output dynamic |

The voltage change is less than±10% VO; the dynamic response time is less than 250us |

mV |

LOAD 25%-50%-25% 50%-75%-50% |

|

|

3 |

Protection character | ||||

|

Item |

Description |

Tech Spec |

Unit |

Remark |

|

|

3.1 |

Input under-voltage protection |

135-165 |

VAC |

Test conditions: full load |

|

|

3.2 |

Input under-voltage recovery point |

140-170 |

VAC |

|

|

|

3.3 |

Output current limiting protection point |

46-60 |

A |

HI-CUP hiccups self-recovery, avoid long-term damage to power after a short-circuit power. |

|

|

3.4 |

Output short circuit protection |

Self-Recovery |

A |

||

|

3.5 |

over temperature protection |

/ |

|

|

|

|

4 |

Other character | ||||

|

Item |

Description |

Tech Spec |

unit |

Remark |

|

|

4.1 |

MTBF |

≥40,000 |

H |

|

|

|

4.2 |

Leakage Current |

<1(Vin=230Vac) |

mA |

GB8898-2001 test method |

|

Production Compliance Characteristics

|

Item |

Description |

Tech Spec |

Remark |

|

|

1 |

Electric Strength |

Input to output |

3000Vac/10mA/1min |

No arcing, no breakdown |

|

2 |

Electric Strength |

Input to ground |

1500Vac/10mA/1min |

No arcing, no breakdown |

|

3 |

Electric Strength |

Output to ground |

500Vac/10mA/1min |

No arcing, no breakdown |

Relative Data Curve

Relationship between environmental temperature and load

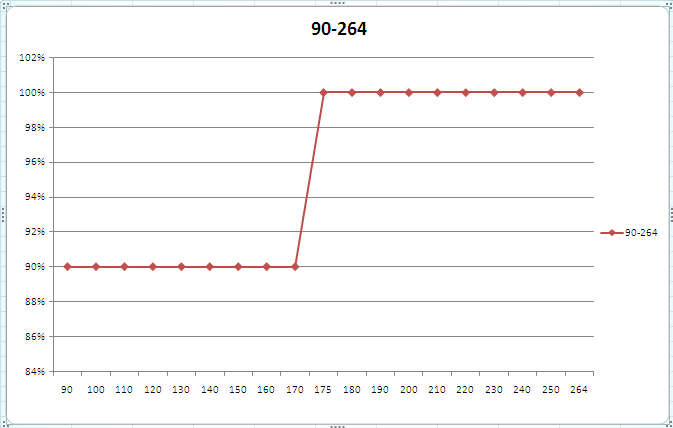

Input voltage and load voltage curve

Load and efficiency curve

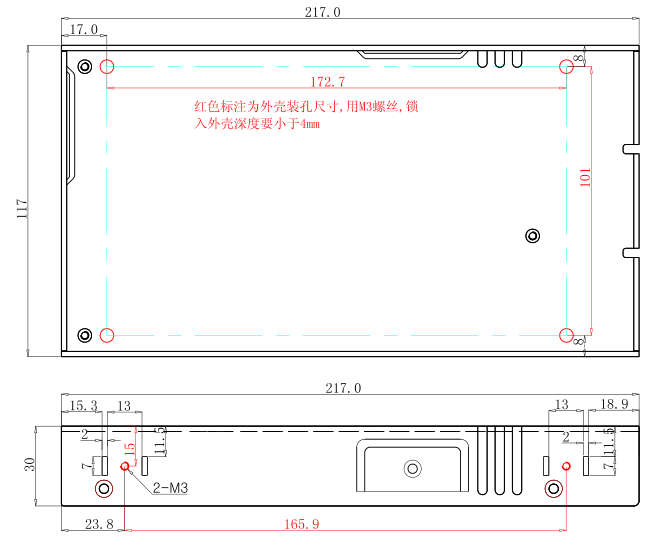

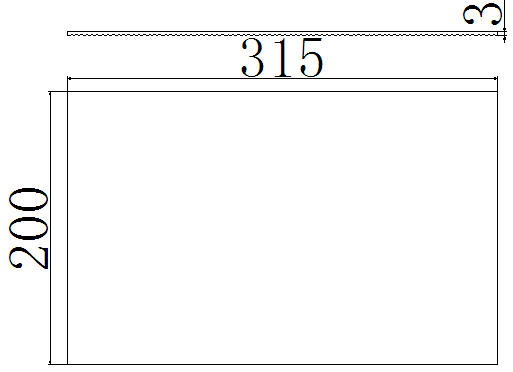

The mechanical character and the definition of connectors( unit:mm)

Dimensions: length× width× height=140×59×30±0.5.

Assembly Holes Dimensions

Above is the top view of the bottom shell. The specifications of the screws fixed in the customer system are M3, totaling 4. The length of the fixed screws entering the power supply body should not exceed 3.5mm.

Attention For Application

- Power supply to be safe insulation, any side of the metal shell with the outside should be more than 8mm safe distance. If less than 8mm need to pad 1mm thickness above PVC sheet to strengthen the insulation.

- Safe use, to avoid contact with the heat sink, resulting in electric shock.

- PCB board mounting hole stud diameter not exceeding 8mm.

- Need a L315mm*W200mm*H3mm aluminum plate as auxiliary heat sink.

If I lose my screen RCG file, how can I get it back ?

A: You can click “read back” to get it back in the software receiver page if you or provider have saved it before.

How to upgrade the firmware of Novastar cards?

A: In NovaLCT advanced mode, anywhere input admin, the upgrade page will come up.

What is the loading capacity of one sending card LAN port ?

A: One LAN port load maximum 655360 pixels.

Do I need to choose synchronous system or asynchronous system?

A: If you need to play the video in real time, like stage LED display, you need to choose synchronous system. If you need to play an AD video for some time, and even not easy to put a PC near it, you need asynchronous system, like shop front advertising LED screen.

What is your best service?

A: One to one sales engineer to customer responsibility system. We will do:

1. Know your project and provide the best solution for it;

2. Track your order and let you know each step and detail of it;

3. Teach you how to install and use the screen;

4. Care the subsequent use of your screen and ensure your after - sales service be well,

5…6…etc.

How about your Warranty Term?

A: Don’t worry, we have professional after-sale team to solve your any questions after you placed an order. And your exclusive sales engineer will also help you get over any problems.

How to deliver the my goods?

A: It depends on your budget and the date you need the led screen. Regularly, the led displays are shipped by sea, if the quantity is less and you need it urgently, we can arrange air-shipping for you.

Is this video processor support Nova control system?

A: Yes, our video processor is a universal mode, support most control system such as Linsn/ Colorlight/ Nova/Dbstar and so on.

How to proceed an order for led display?

A: First: Let us know your requirements or application.

Second: We will provide you the best solution with suitable product according to your requirements and recommend.

Third: We will send you the complete quotation with detailed specifications for your needed, also send you more detailed pictures of our products

Fourth: After received the deposit, then we arrange the production.

Fifthly: During the produce, we will send the product test pictures to customers, let customers know every production process

Sixth: Customers pay the balance payment after confirmation of the finished product.

Seventh: We arrange the shipment

What about the lead time?

A: Sample needs 15 days, mass production time needs 3-5 weeks depends on the quantities.

What is your lead time?

A: The delivery time is 1-30 days which depend on detail and quantity.

Do you accept OEM/ODM?

A: Yes.

What's the difference between back service and front service led screen ?

A: Back service, that mean need enough space behind of the led screen, so that worker can do the installation or maintenance.

Front service, worker can do installation and maintenance from front directly. very convenience, and save space. especially is that led screen will fixed on the wall.

Can I have a sample order for LED products?

A: Yes, we welcome sample order to test and check quality.

-300x300.jpg)