G-energy JPS200V5-A 110V/220V 5V 40A LED Power Supply

Product Main Specification

|

Output Power (W) |

Rated Input Voltage (Vac) |

Rated Output Voltage (Vdc) |

Output Current Range (A) |

Precision |

Ripple and Noise (mVp-p) |

|

200 |

110/220 |

+5.0 |

0-40 |

±2% |

≤200 |

Environment Condition

|

Item |

Description |

Tech Spec |

Unit |

Remark |

|

1 |

Working temperature |

-30—60 |

℃ |

Please refer to "temperature decrement curve" |

|

2 |

Storing temperature |

-40—85 |

℃ |

|

|

3 |

Relative humidity |

10—90 |

% |

No condensation |

|

4 |

Heat dissipation method |

Air cooling |

|

|

|

5 |

Air pressure |

80— 106 |

Kpa |

|

|

6 |

Height of sea level |

2000 |

m |

Electrical Character

|

1 |

Input character | ||||

|

Item |

Description |

Tech Spec |

Unit |

Remark |

|

|

1.1 |

Rated voltage range |

200-240 |

Vac |

Refer to the diagram of input voltage and load relation. |

|

|

1.2 |

Input frequency range |

47—63 |

Hz |

|

|

|

1.3 |

Efficiency |

≥85.0 |

% |

Vin=220Vac 25℃ Output Full Load (at room temperature) |

|

|

1.4 |

Efficiency factor |

≥0.40 |

|

Vin=220Vac Rated input voltage, output full load |

|

|

1.5 |

Max input current |

≤3 |

A |

|

|

|

1.6 |

Dash current |

≤70 |

A |

@220Vac Cold state test @220Vac |

|

|

2 |

Output character | ||||

|

Item |

Description |

Tech Spec |

Unit |

Remark |

|

|

2.1 |

Output voltage rating |

+5.0 |

Vdc |

|

|

|

2.2 |

Output current range |

0-40.0 |

A |

|

|

|

2.3 |

Output voltage adjustable range |

4.2-5.1 |

Vdc |

|

|

|

2.4 |

Output voltage range |

±1 |

% |

|

|

|

2.5 |

Load regulation |

±1 |

% |

|

|

|

2.6 |

Voltage stability accuracy |

±2 |

% |

|

|

|

2.7 |

Output ripple and noise |

≤200 |

mVp-p |

Rated input, output full load, 20MHz bandwidth, load side and 47uf / 104 capacitor |

|

|

2.8 |

Start output delay |

≤3.0 |

S |

Vin=220Vac @25℃ test |

|

|

2.9 |

Output voltage raise time |

≤90 |

ms |

Vin=220Vac @25℃ test |

|

|

2.10 |

Switch machine overshoot |

±5 |

% |

Test conditions: full load, CR mode |

|

|

2.11 |

Output dynamic |

The voltage change is less than±10% VO; the dynamic response time is less than 250us |

mV |

LOAD 25%-50%-25% 50%-75%-50% |

|

|

3 |

Protection character | ||||

|

Item |

Description |

Tech Spec |

Unit |

Remark |

|

|

3.1 |

Input under-voltage protection |

135-165 |

VAC |

Test conditions: full load |

|

|

3.2 |

Input under-voltage recovery point |

140-170 |

VAC |

|

|

|

3.3 |

Output current limiting protection point |

46-60 |

A |

HI-CUP hiccups self-recovery, avoid long-term damage to power after a short-circuit power. |

|

|

3.4 |

Output short circuit protection |

Self-Recovery |

A |

||

|

3.5 |

over temperature protection |

/ |

|

|

|

|

4 |

Other character | ||||

|

Item |

Description |

Tech Spec |

unit |

Remark |

|

|

4.1 |

MTBF |

≥40,000 |

H |

|

|

|

4.2 |

Leakage Current |

<1(Vin=230Vac) |

mA |

GB8898-2001 test method |

|

Production Compliance Characteristics

|

Item |

Description |

Tech Spec |

Remark |

|

|

1 |

Electric Strength |

Input to output |

3000Vac/10mA/1min |

No arcing, no breakdown |

|

2 |

Electric Strength |

Input to ground |

1500Vac/10mA/1min |

No arcing, no breakdown |

|

3 |

Electric Strength |

Output to ground |

500Vac/10mA/1min |

No arcing, no breakdown |

Relative Data Curve

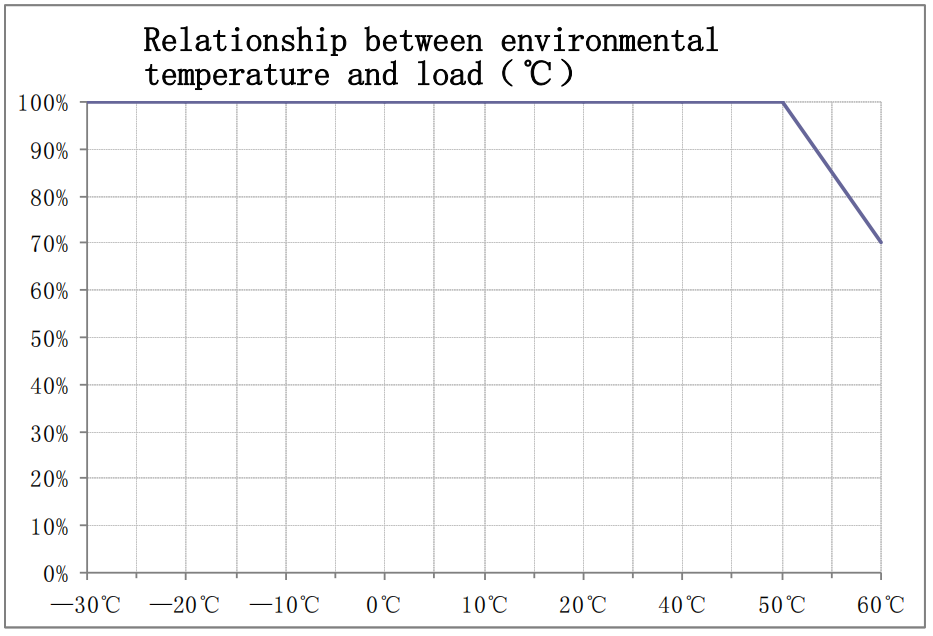

Relationship between environmental temperature and load

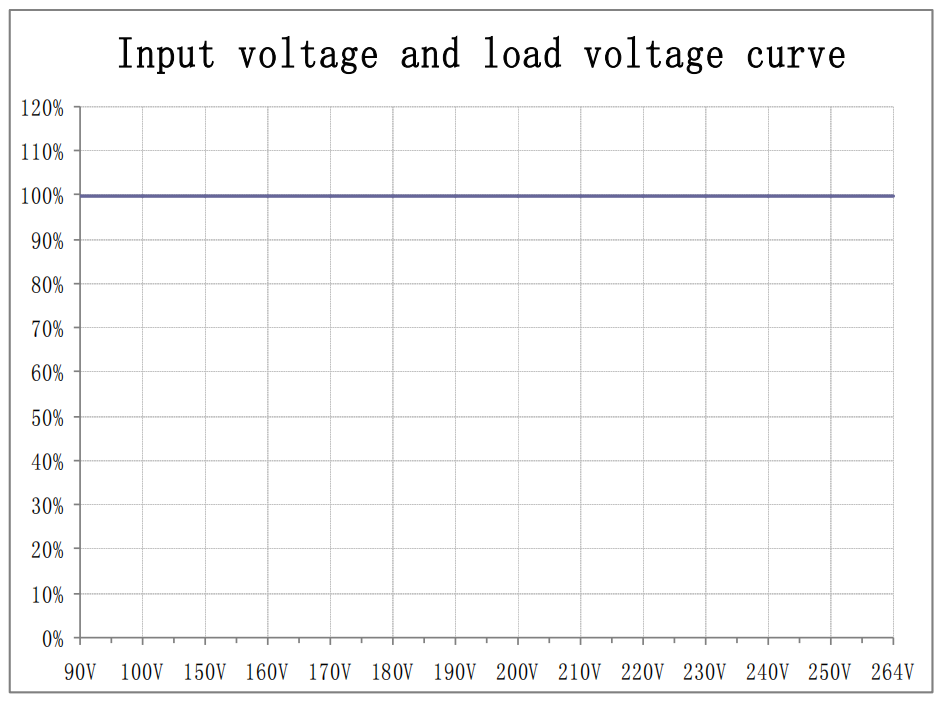

Input voltage and load voltage curve

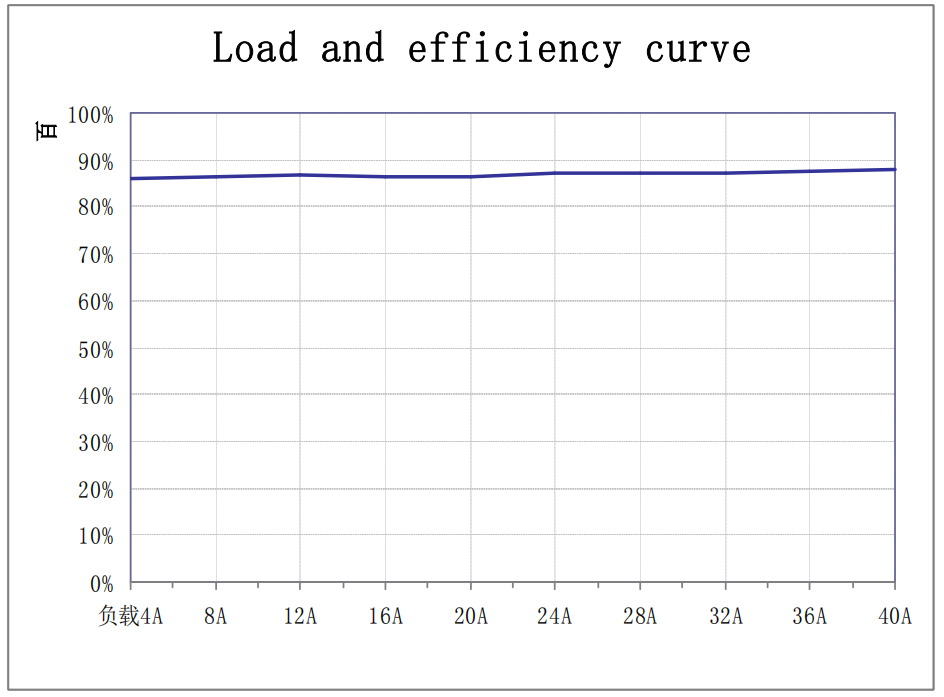

Load and efficiency curve

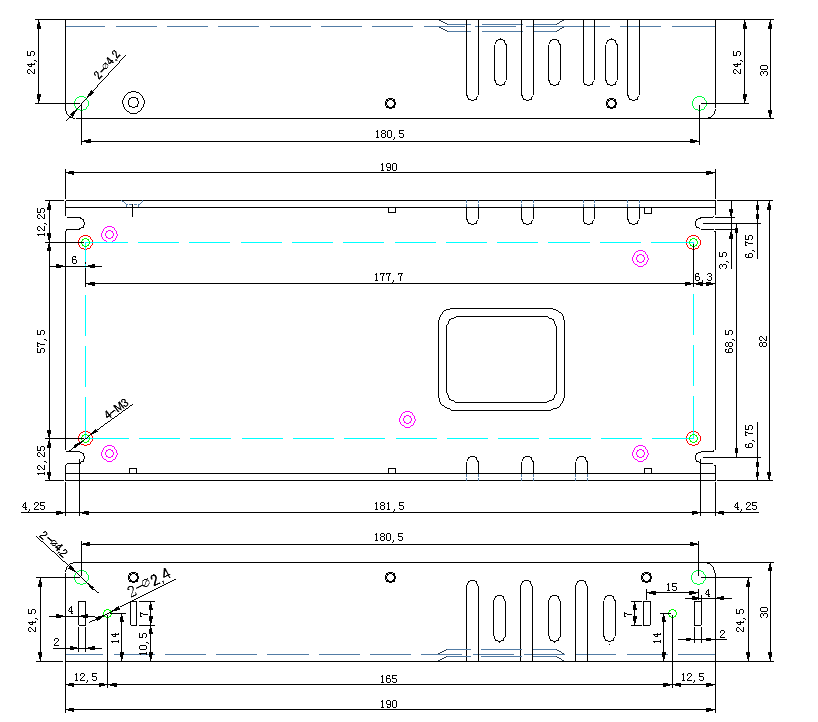

The mechanical character and the definition of connectors( unit:mm)

Dimensions: length× width× height=140×59×30±0.5.

Assembly Holes Dimensions

Safe use, to avoid contact with the heat sink, resulting in electric shock.

High-voltage electricity inside, please don`t open unless professionals

Must be installed vertically, inversely or horizontally are not allowed

Keep objects 10 cm away for convection

Brightness control D/T conversion technology

LED electronic display is composed of many independent pixels by arrangement and combination. Based on the feature of separating pixels from each other, LED electronic display can only expand its luminous control driving mode through digital signals. When the pixel is illuminated, its luminous state is mainly controlled by the controller, and it is driven independently. When the video needs to be presented in color, it means that the brightness and color of each pixel need to be effectively controlled, and the scanning operation is required to be completed synchronously within a specified time.

Some large LED electronic displays are composed of tens of thousands of pixels, which greatly increases the complexity in the process of color control, so higher requirements are put forward for data transmission. It is not realistic to set D/A for each pixel in the actual control process, so it is necessary to find a scheme that can effectively control the complex pixel system.

By analyzing the principle of vision, it is found that the average brightness of a pixel mainly depends on its bright-off ratio. If the bright-off ratio is effectively adjusted for this point, the effective control of brightness can be achieved. Applying this principle to LED electronic displays means converting digital signals into time signals, that is, the conversion between D/A.